Introduction:

Wood Plastic Composite (WPC) doors have gained significant popularity in recent years due to their unique combination of durability, environmental friendliness, and aesthetic appeal. As the demand for sustainable and long-lasting door solutions continues to grow, manufacturers have been investing in research and development to enhance the technology and applications of WPC doors. In this blog post, we will explore the latest advancements in WPC door technology, focusing on new formulations and specialized manufacturing processes that have revolutionized the industry.

- New Formulations Revolutionizing WPC Doors:

1.1 Enhanced Durability and Environmental Friendliness

The latest WPC door formulations have been engineered to offer exceptional durability, surpassing traditional wooden doors. By incorporating high-quality wood fibers and recycled plastic materials, manufacturers have created a composite material that is resistant to rot, decay, and insect damage. Additionally, these new formulations prioritize environmental sustainability by reducing the reliance on virgin plastic and promoting the use of recycled materials.

1.2 Improved Resistance to Wear and Scratches

One of the key advancements in WPC door technology is the development of enhanced wear and scratch resistance. Through innovative additives and surface treatments, manufacturers have significantly improved the door’s ability to withstand daily wear and tear. This makes WPC doors an ideal choice for high-traffic areas, such as commercial buildings and residential properties.

1.3 Advanced Oil Resistance for Longevity

To further enhance the longevity of WPC doors, manufacturers have introduced advanced oil-resistant formulations. These formulations provide an additional layer of protection against oil stains and spills, making the doors easier to clean and maintain. This feature is particularly beneficial in areas prone to frequent contact with oils, such as kitchens and restaurants.

1.4 Unmatched Toughness for Enhanced Security

WPC doors have always been known for their toughness, but the latest formulations have taken it to a whole new level. By incorporating specialized additives and reinforcing fibers, manufacturers have significantly increased the door’s impact resistance and overall strength. This makes WPC doors an excellent choice for security-conscious customers who prioritize both aesthetics and protection.

- Specialized Integrated Manufacturing Process:

2.1 Upgraded One-Piece Integration Technology

The integration of wood fibers and plastic materials in WPC doors has traditionally involved multiple steps and processes. However, recent advancements in manufacturing techniques have led to the development of one-piece integration technology. This innovative process allows for a seamless fusion of the components, resulting in a stronger and more durable end product. Additionally, the one-piece integration technology eliminates the risk of delamination, ensuring the longevity of the doors.

2.2 Increased Efficiency and Quality

The new manufacturing processes have not only improved the strength and durability of WPC doors but also increased production efficiency and quality. With the integration of automated systems and advanced machinery, manufacturers can now produce doors at a faster rate without compromising on quality. This has led to shorter lead times and improved customer satisfaction.

2.3 Competitive Pricing for WPC Doors

Another significant advantage of the upgraded manufacturing processes is the ability to offer WPC doors at a more competitive price point. The increased efficiency and streamlined production have resulted in cost savings, which can be passed on to the customers. This makes WPC doors a cost-effective alternative to traditional wooden doors without compromising on quality or aesthetics.

- Advantages of Upgraded Packaging Techniques:

3.1 Customized Packaging Solutions for Different Customer Needs

Recognizing the diverse requirements of customers, manufacturers have upgraded their packaging techniques to offer customized solutions. Whether it’s bulk shipments for large-scale projects or individual packaging for retail customers, the new packaging techniques ensure that the doors are protected during transportation and arrive in pristine condition.

3.2 Ensuring Safe Transportation and Delivery

The upgraded packaging techniques not only focus on protecting the doors but also prioritize safe transportation and delivery. By incorporating shock-absorbing materials and secure packaging methods, manufacturers can minimize the risk of damage during transit. This ensures that customers receive their orders intact and ready for installation.

3.3 Enhanced Branding and Customer Experience

Packaging is not just about protection; it also plays a crucial role in branding and customer experience. Manufacturers have recognized this and have invested in upgraded packaging designs that reflect their brand identity and create a positive impression on customers. Additionally, informative labels and instructions make it easier for customers to handle and install the doors, enhancing their overall experience.

- Addressing Customer Needs with WPC Doors:

4.1 Meeting the Demand for Eco-Friendly Solutions

In today’s environmentally conscious world, customers are increasingly seeking sustainable alternatives to traditional products. WPC doors, with their use of recycled materials and reduced carbon footprint, perfectly align with this demand. The latest advancements in WPC door technology have further enhanced their eco-friendly attributes, making them an ideal choice for environmentally conscious customers.

4.2 Catering to the Growing Market for Durable Doors

Durability is a key consideration for customers when choosing doors for their homes or commercial spaces. WPC doors, with their enhanced resistance to wear, scratches, and impact, offer unmatched durability compared to traditional wooden doors. The latest technologies and formulations have taken this durability to new heights, ensuring that WPC doors can withstand the test of time and maintain their aesthetic appeal.

4.3 Providing Cost-Effective Alternatives

Cost is often a deciding factor for customers when selecting doors. The upgraded manufacturing processes and competitive pricing of WPC doors make them an attractive option for budget-conscious customers. By offering a cost-effective alternative to traditional wooden doors without compromising on quality or aesthetics, WPC doors provide excellent value for money.

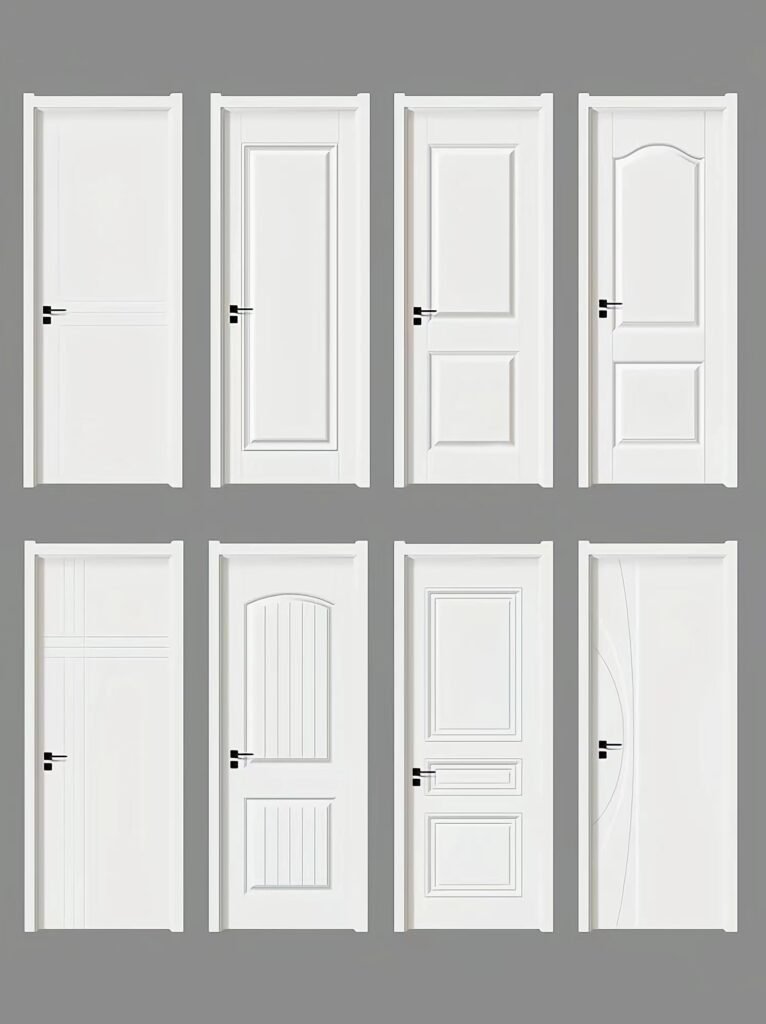

4.4 Offering Versatile Design Options

WPC doors are available in a wide range of designs, finishes, and colors, allowing customers to find the perfect match for their interior or exterior spaces. The latest advancements in technology have further expanded the design possibilities, enabling manufacturers to create doors that mimic the natural beauty of wood while offering the benefits of WPC. From traditional to contemporary styles, WPC doors offer versatility and customization options to suit every customer’s preference.

- Highlighting Core Advantages of Our WPC Doors:

5.1 Unparalleled Durability and Longevity

Our WPC doors are engineered using the latest formulations and manufacturing processes, ensuring exceptional durability and longevity. With enhanced resistance to wear, scratches, and impact, our doors are built to withstand the rigors of daily use and maintain their aesthetic appeal for years to come.

5.2 Exceptional Resistance to Wear, Scratches, and Oil

We prioritize the development of WPC doors that offer unmatched resistance to wear, scratches, and oil. Our advanced formulations and surface treatments ensure that our doors can withstand the demands of high-traffic areas and remain easy to clean and maintain.

5.3 Enhanced Security and Toughness

Security is a top priority for many customers, and our WPC doors are designed to provide enhanced security and toughness. With specialized additives and reinforcing fibers, our doors offer superior impact resistance and strength, providing peace of mind to our customers.

5.4 Environmentally Friendly and Sustainable Choice

We are committed to sustainability, and our WPC doors reflect this commitment. By utilizing recycled materials and reducing our carbon footprint, our doors offer an environmentally friendly alternative to traditional wooden doors. Choosing our WPC doors means making a responsible choice for the planet.

Conclusion:

The latest technologies and applications in wood plastic composite (WPC) doors have revolutionized the industry, offering enhanced durability, environmental friendliness, and competitive pricing. With new formulations and specialized manufacturing processes, WPC doors have become the go-to choice for customers seeking sustainable, long-lasting, and aesthetically pleasing door solutions. From improved resistance to wear, scratches, and oil to advanced integration techniques and upgraded packaging, WPC doors offer numerous advantages for both residential and commercial applications. Explore our website and blog to learn more about our high-quality WPC doors and how they can transform your spaces.